General Machinery

Cost-effective: Provides cost-effective tools to optimize production costs.

Quick changeover: Quick tool change system for increased production flexibility and responsiveness.

Material versatility: Develop universal tools for machining a wide range of materials to reduce inventory requirements.

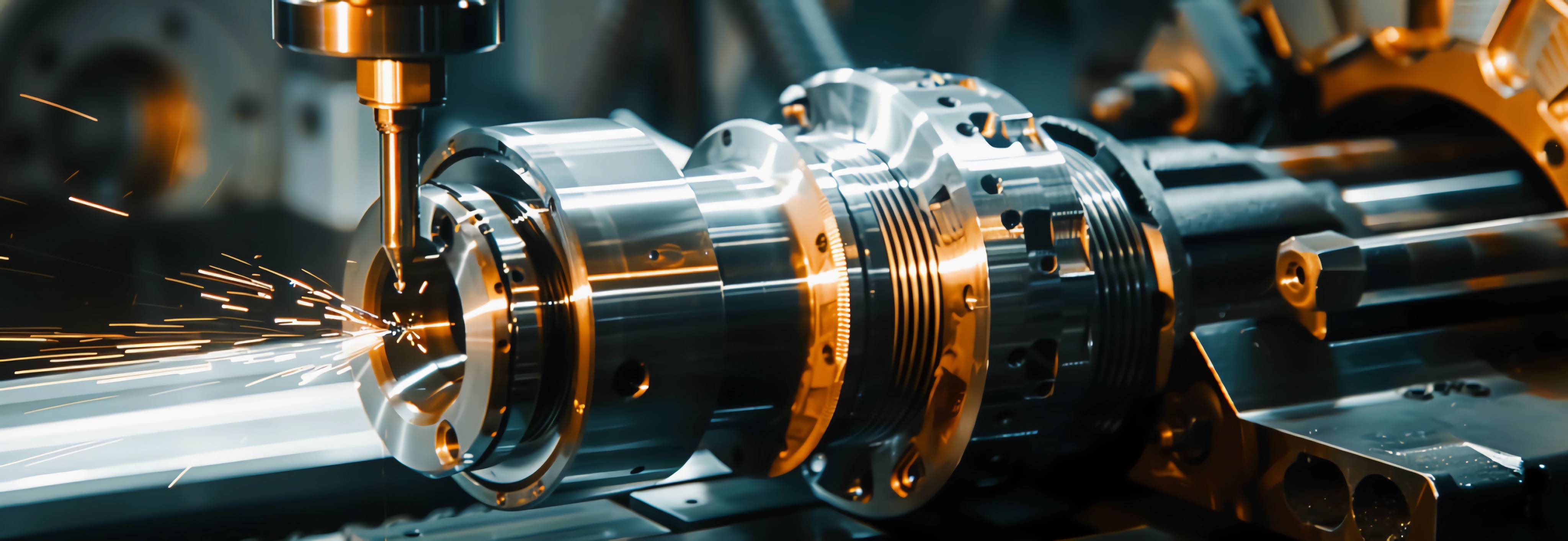

Machine Tool Industry

High precision: Precision tools are provided to ensure high repeatability and consistency in machine tool machining.

Versatility: Design multifunctional tools to adapt to different machining needs and reduce the number of tool changes.

Technology integration: Integration of the latest technologies, such as intelligent monitoring, to improve the intelligence of machine tool processing.

Construction Machinery

Durability: Development of highly durable carbide tools designed for long term heavy duty operations.

Adaptability: Suitable for variable engineering environments and guaranteed performance in outdoor or harsh conditions

Easy maintenance: Designed for easy maintenance, the tooling system reduces downtime and improves operational efficiency.

Automobile Industry

Lightweight: Provides lightweight and efficient cutting tools for the trend of automotive lightweighting.

Automation Compatibility: Tools are designed with automated production line compatibility in mind for easy integration.

Surface Finishing: Focused on providing tools that achieve a high quality surface finish.

Mold Industry

Responding to complexity: Designing high-precision tools for complex and fine mold machining.

Design optimization: Collaborate with customers to provide optimized toolpath design to reduce machining time.

Material expertise: Provide professional tooling solutions for special materials in the mold industry.

Rail Transit

Safety: Provide durable knives that meet railroad safety standards.

High-precision manufacturing: Ensures high-precision machining of components to meet strict industry specifications.

Impact-resistant design: The tool is designed to be impact-resistant and adaptable to high-load machining environments.

Aerospace

Machining of lightweight materials: Specialized tools for lightweight, high-strength materials in the aerospace sector.

Ultra-precision machining: Provides ultra-precision machining solutions to meet extreme precision requirements.

High-temperature-resistant alloy: R&D of high-temperature-resistant alloy tools to meet the needs of special material processing.

Petrochemical Industry

Corrosion resistance: Provides corrosion resistant tools for chemical and marine environments.

High-temperature stability: High-temperature-resistant tools to ensure performance in high-temperature operating environments.

Safety standards: Comply with the safety operation standards of the petrochemical industry to ensure operational safety.

TEL:

TEL: Email:

Email: Address:

Address: