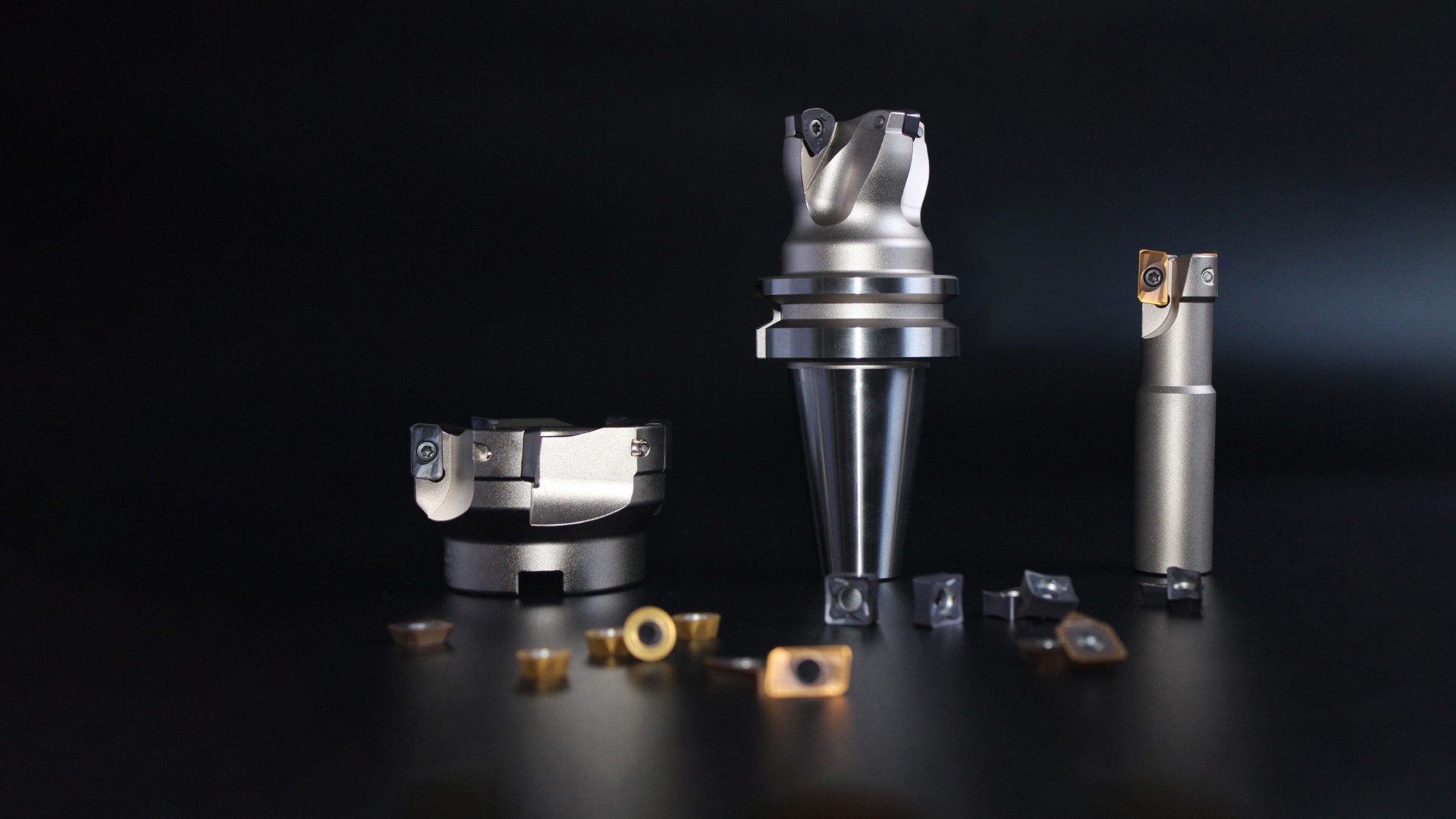

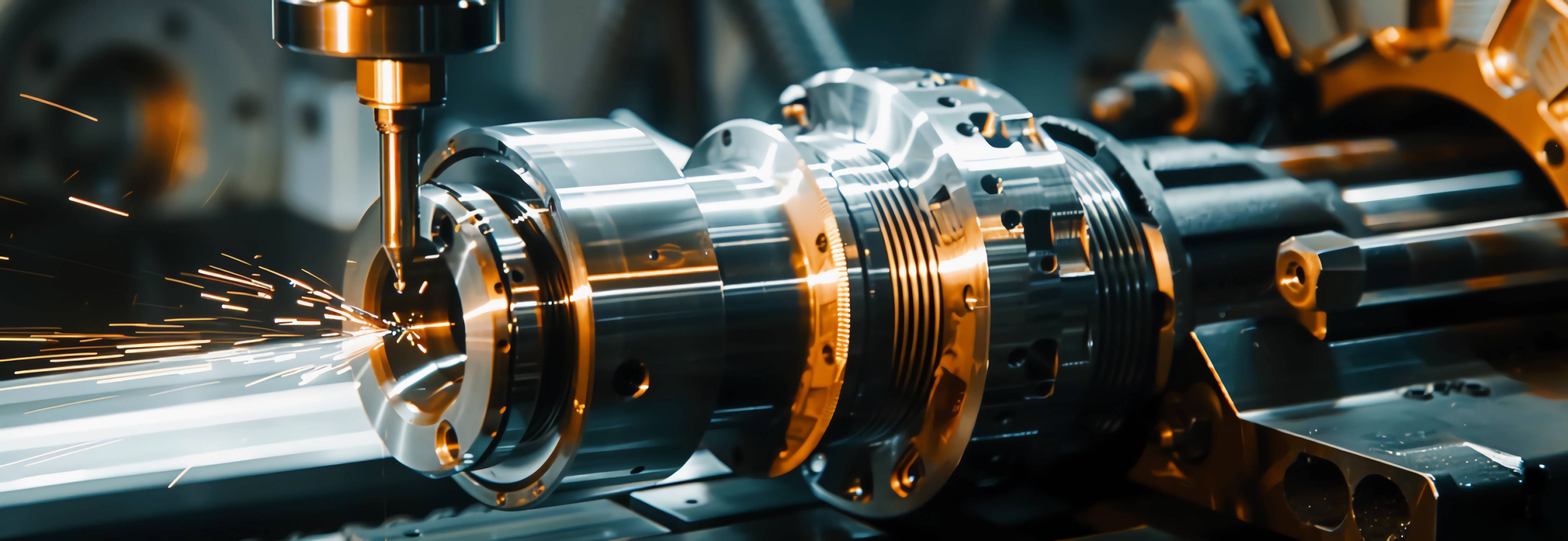

Eddie Rinex has a rich and diverse product system, including four major series of products: CNC blade series, hard alloy rod cutter series, steel tool series, gear tool series, etc;

In order to ensure the accuracy of gear cutting tools, the company has introduced testing equipment to conduct comprehensive testing on finished cutting tools, including tooth profile, tooth direction, runout, tooth thickness, etc. The company has formed an annual output of 2,400 hobbing knives, an annual output of 600 gear shaper knives and an annual production capacity of 16,000 gear tools.

TEL:

TEL: Email:

Email: Address:

Address: